Thinking about how buildings stay safe from fire hazards makes me think of fire safety strips. These strips are key to keeping fires from spreading. They are placed on fire doors to seal them tight when it gets hot.

Putting in fire prevention solutions like fire strips is very important. It helps keep people and things safe. In this article, I’ll show you how to install fire strips safely. We’ll focus on the right way to do it.

Key Takeaways

- Understanding the role of fire strips in fire safety

- Preparing for safe installation

- Step-by-step guide to installing fire strips

- Importance of proper installation techniques

- Ensuring compliance with fire safety regulations

Understanding the Importance of Fire Strips

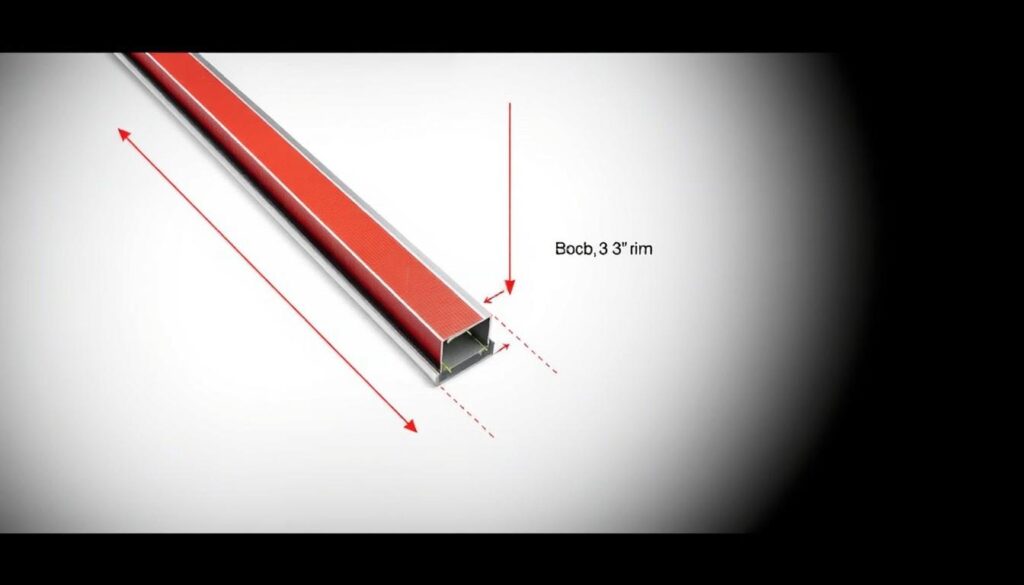

To improve fire safety, it’s key to know what fire strips are and how they work. Fire strips, also called intumescent strips, grow when it gets very hot. They seal gaps around fire doors, stopping smoke and fire from spreading.

What Are Fire Strips?

Fire strips are fire-resistant products that are vital for fire safety. They’re made from materials that can handle extreme heat. These materials expand when heated, sealing gaps between a fire door and its frame. This stops flames and hot gases from passing through.

Why Use Fire Strips in My Home?

Using flame retardant strips in your home boosts fire safety. These strips help keep fires contained and stop smoke from spreading. This is important for giving more time to evacuate and lessening damage.

| Benefits of Fire Strips | Description |

|---|---|

| Prevents Fire Spread | Seals gaps around fire doors to prevent flames from passing through. |

| Reduces Smoke Damage | Limits the spread of smoke to other areas, reducing overall damage. |

| Enhances Evacuation Time | By containing fires and smoke, it provides more time for safe evacuation. |

In conclusion, adding fire strips to your home’s fire safety plan is a smart move. It helps protect your family and property. By understanding their role, you can make better choices for your home’s safety.

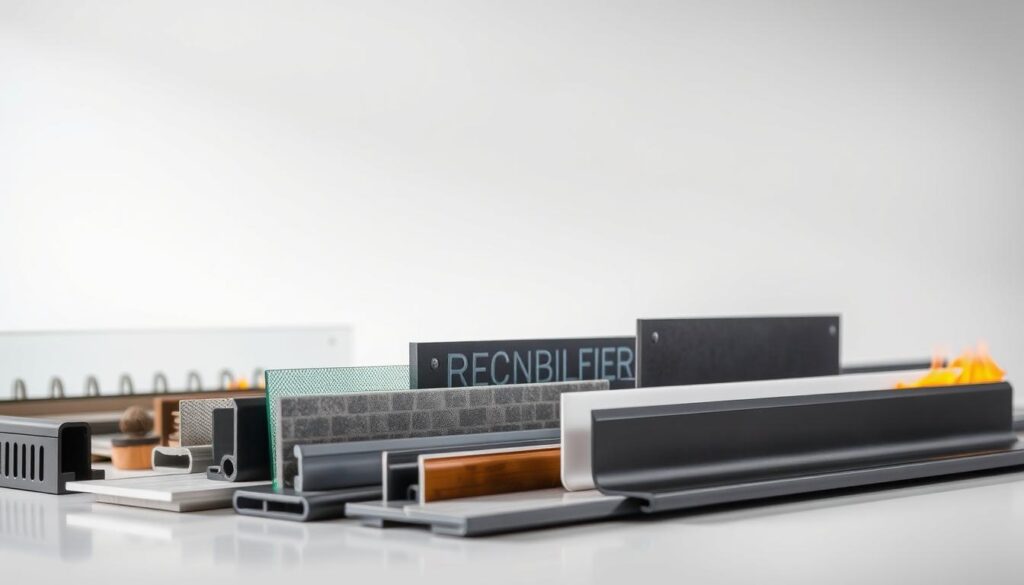

Types of Fire Strips Available

The market has many fire strips, each with its own features and uses. Knowing these differences helps you pick the right fire strip for your needs.

Foam Fire Strips

Foam fire strips are easy to install and work well in many places. They are made from materials that grow when it gets hot. This helps seal gaps and stop fires from spreading. For more details, check out intumescent strips FAQs.

Rubber Fire Strips

Rubber fire strips are flexible and last long. They’re great for places that move or vibrate a lot. They also stand up well to the weather.

Metal Fire Strips

Metal fire strips are very fire-resistant. They’re often used in tough environments. They offer strong fire protection, perfect for industrial or commercial areas.

A fire safety expert says, “The right fire strip can greatly improve a building’s fire safety.” It’s important to think about what you need and choose a fire strip that fits those needs.

Tools I Need for Installation

Having the right tools is key for a successful fire strip installation. Before starting, it’s important to gather all needed tools and safety gear. This ensures a smooth and safe installation.

Essential Tools for the Job

To install intumescent strips, I need a few important tools. A router is needed to create grooves for the strips. I also use a knife or scissors to cut the strip to size. Plus, a clean, damp cloth is used to clean the surface before applying the fire strip.

Safety Gear I Always Use

Safety gear is vital during installation. I always wear protective gloves to prevent injuries from sharp edges or tools. For more information on safely installing intumescent strips, you can visit this resource which provides detailed guidance on the installation process.

By having the right tools and safety gear, I can ensure a successful and safe fire strip installation. This enhances the fire safety of the premises.

Preparing for Installation

I always start by checking the areas that need fire strips. This first step is key for a good installation.

Assessing Areas Needing Fire Strips

To find out where fire protection strips are needed, I walk through my home. I look for gaps and joints around doors, windows, and other fire paths. It’s important to check for damage or wear that could impact the installation.

I make a list of all the places that need flame retardant strips. This ensures I don’t miss any important spots. A detailed assessment helps me plan the installation better.

Measuring Spaces Accurately

Getting the measurements right is essential for a good fit. I use a tape measure to record the length and width of the spaces for the fire strips. I also note any surface irregularities.

By measuring accurately, I can make sure the fire strips fit perfectly. This careful planning is a big part of getting ready for the installation.

Step-by-Step Installation Process

Installing fire safety strips is easy but needs careful attention. Follow these steps for a successful installation.

Cleaning the Surface

First, clean the surface well. Dirt, dust, and old adhesives can weaken the fire strips. I use a soft cloth and gentle cleanser to clean it. Make sure it’s dry before moving on.

Applying Adhesive (If Necessary)

Some fire strips come with adhesive. Others need you to apply it. If your strips need adhesive, pick the right one for your surface. Always follow the manufacturer’s guide to avoid mistakes.

Placing the Fire Strips

Now, place the fire strips on the surface. Measure the area first for a perfect fit. Cut the strips if needed. Apply them firmly, starting from one end. Make sure there are no air bubbles or gaps.

- Ensure the surface is dry and clean before applying fire strips.

- Use the correct adhesive for your surface type.

- Avoid stretching or pulling the fire strips during application.

- Inspect the fire strips after installation for any gaps or air bubbles.

By following these steps and tips, you can install fire safety strips well. This will improve your home’s fire safety. Remember, the key is to pay attention to detail and prepare well.

Common Mistakes to Avoid

Understanding common mistakes is key for a successful fire strip installation. Knowing the pitfalls helps ensure safety and integrity of fire-resistant products.

Two major errors are miscalculating measurements and skipping surface preparation. Let’s explore these mistakes and how to sidestep them.

Miscalculating Measurements

Miscalculating measurements is a common mistake. It can cause inadequate coverage or wasted material. To avoid this, I double-check my measurements and use a tape measure for accuracy.

- Measure the space where the fire strip will be applied carefully.

- Consider any obstructions or irregularities in the surface.

- Use a calculator to ensure you’re ordering the correct amount of material.

Skipping Surface Preparation

Another mistake is skipping surface preparation. Not cleaning the surface properly can lead to poor adhesion of the fire strip. This can compromise its effectiveness. To avoid this, I thoroughly clean the surface before applying the fire strip.

- Clean the surface with a degreaser to remove dirt and grime.

- Ensure the surface is dry before applying the fire strip.

- Check for any rough spots or debris that could interfere with adhesion.

By avoiding these common mistakes, you can ensure a successful fire strip installation. This provides effective fire protection for your home or business.

Checking for Compliance

After installing fire strips, I must check if my work meets safety standards and building codes. This step is key to ensure my installation offers the fire safety it’s meant to.

Building codes and safety standards are there to protect people and property. As a homeowner or installer, knowing these rules is vital to avoid legal and safety problems.

Understanding Building Codes

Building codes outline the rules for construction, including fire safety. For fire strips, these codes specify the material, size, and how to install them. It’s essential to know these codes to ensure compliance.

Some key aspects covered by building codes include:

- The type of fire strip material allowed (e.g., foam, rubber, metal)

- The dimensions and specifications of the fire strips

- The correct installation procedures to ensure effectiveness

Ensuring My Installation Meets Safety Standards

To confirm my fire strip installation meets safety standards, I need to check it against the building codes. This means verifying the materials, installation method, and ensuring all work is inspected and certified if needed.

| Building Code Aspect | Description | Compliance Check |

|---|---|---|

| Material Specification | Specifies the type of material to be used for fire strips. | Verify that the material used matches the code requirements. |

| Installation Method | Details the correct procedure for installing fire strips. | Ensure that the installation method complies with the specified code. |

| Inspection and Certification | Requires inspection and possibly certification of the installed fire strips. | Arrange for necessary inspections and obtain certification if required. |

By following these guidelines and ensuring my installation meets building codes and safety standards, I can be confident in my fire safety measures.

Maintaining Fire Strips

Keeping fire strips in good condition is key to my home’s safety. After they’re installed, it’s important to check if they’re working right. Look for any damage or if they’ve come loose.

Regular Inspections I Perform

I check the fire strips often for wear or damage. I look for gaps or if they’ve come off the surface. I also check for any damage to the strips themselves.

When I inspect, I make sure they’re aligned right. I also check if the adhesive is strong. This helps spot problems early.

Signs That Indicate Replacement

There are clear signs when fire strips need to be replaced. Look for cracks, tears, or if they’ve come off. If I see these, it’s time to get new ones for my home’s safety.

Even if they look fine, extreme conditions like high heat or moisture can damage them. Regular checks help me see when they need to be replaced.

Benefits of Professional Help

Hiring a professional to install fire strips can give you peace of mind. It ensures you follow safety standards. DIY installation works for some, but professionals are key in many cases.

Fire safety is critical, and small errors can lead to big problems. Fire safety strips are vital for preventing fires. Their correct installation is key to their success.

When to Call a Professional

There are times when you should get a professional for fire strip installation. For complex buildings or large areas, a pro can do the job right. They also know the local building codes and fire prevention solutions rules.

Here are some situations where you should get professional help:

- Complex installations with many parts or hard-to-reach spots.

- Uncertainty about local building codes or fire safety rules.

- Big installations that need a lot of time and effort.

Cost vs. DIY Installation

Cost is a big factor when choosing between DIY and professional installation. Professionals might seem pricier at first, but they offer long-term benefits. A well-installed fireproof strips system lasts longer and works better, saving you money in the long run.

Let’s look at the costs of DIY versus professional installation:

| Cost Factor | DIY Installation | Professional Installation |

|---|---|---|

| Initial Cost | Lower (just materials) | Higher (labor and materials) |

| Long-term Cost | Potential for more maintenance and replacement costs | Less maintenance and replacement costs because of quality installation |

| Compliance and Safety | Risk of not following rules and safety issues if not done right | Guaranteed compliance and better safety |

In summary, while DIY fire strip installation is possible, hiring a pro is often better. The extra cost of professional installation is worth it for the long-term savings and peace of mind. Knowing your fire safety strips are installed correctly and safely is priceless.

Environmental Considerations

When thinking about installing fire strips in my home, I also think about their environmental impact. It’s key to consider if fire strips are eco-friendly and how to get rid of old or damaged ones right.

Eco-Friendly Options for Fire Strips

Fortunately, there are now eco-friendly fire strip options. These are made from materials that are better for the environment and our health. For example, some are made from recycled materials or sustainable sources.

When picking fire strips, I look for those labeled as eco-friendly or made from recycled content.

Disposal of Old Fire Strips

It’s important to dispose of old or damaged fire strips properly. I should check with local waste management to see how to do this. Some places have special events for hazardous waste, including old fire strips.

If not, I need to follow local rules to avoid harming the environment.

By thinking about the environmental impact of fire strips, I can choose wisely. This way, I balance safety with being eco-friendly.

Final Thoughts

Thinking back on installing fire strips, I see how important they are for home safety. These strips act as a fire barrier, slowing down fire spread. They are a key part of keeping our homes safe from fires.

My Key Takeaways

Installing fire strips requires careful planning and attention to detail. It’s important to choose the right spots and follow building codes. Each step helps create a strong fire barrier.

Staying Proactive About Fire Safety

It’s important to take steps to make your home safer from fires. Using fireproof strips is a great way to lower fire risk. Remember to check and maintain these strips regularly.

Being proactive about fire safety helps keep your family safe. Fire safety strips are an easy, effective way to prevent fires. They can make a big difference in keeping your home safe.

FAQ

What are fire strips, and how do they work?

Fire strips, also known as intumescent strips, expand in high heat. They seal gaps around fire doors to stop fire spread. They are key to keeping buildings safe from fire.

What types of fire strips are available in the market?

The market has foam, rubber, and metal fire strips. Each type has its own features and uses. Knowing the differences helps pick the right one for your needs.

How do I choose the right fire strip for my needs?

Consider the door type, gap size, and fire resistance needed. Also, check if it meets local building codes and safety standards.

What are the essential tools and safety gear required for installing fire strips?

You’ll need a tape measure, utility knife, cleaning solution, gloves, and safety glasses. Having the right tools and safety gear is important for a safe install.

How do I prepare for the installation of fire strips?

First, check where fire strips are needed and measure accurately. Make sure the surface is clean and ready for the strips. Good preparation is essential for a successful install.

What are the common mistakes to avoid during fire strip installation?

Avoid miscalculating measurements and skipping surface prep. Knowing these mistakes can help ensure a good install.

How do I maintain my fire strips?

Regularly check them for wear or damage. Replace them if needed to keep fire safety up.

Are there eco-friendly options available for fire strips?

Yes, eco-friendly fire strip options exist. Choose products made from green materials and dispose of old strips properly to reduce environmental harm.

When should I consider hiring a professional for fire strip installation?

Hire a pro if you’re unsure about the install, need special knowledge or tools, or are uncomfortable with heights or certain materials.

What are flame retardant strips, and are they the same as fire strips?

Flame retardant strips resist ignition and slow fire spread. They’re different from fire strips, which expand in heat to seal gaps. Knowing the difference is key for the right product use.

How do fire seal strips contribute to fire safety?

Fire seal strips seal gaps and joints, stopping fire and smoke spread. They’re vital for fire safety, working with fire strips and other fire-resistant products.

What is the difference between fireproof strips and fire strips?

Fireproof strips withstand fire without damage. Fire strips expand in heat to seal gaps. Both are critical for fire safety, and knowing their differences is essential for the right choice.